News

News Time:2025-07-11

Time:2025-07-11

Reading:854

Reading:854

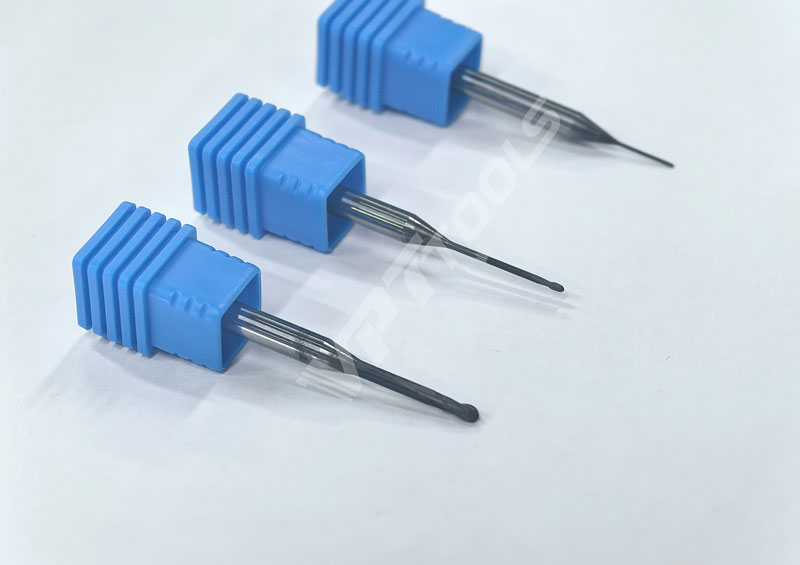

Diamond-coated zirconia milling burs are essential consumables for digital dental restoration, specially optimized for high-speed milling of zirconia and other ultra-hard materials. Utilizing advanced CVD (Chemical Vapor Deposition) technology, these milling burs feature a 2-10μm diamond coating on a tungsten steel base, combining exceptional wear resistance with razor-sharp cutting performance. A single DC milling bur can efficiently process 600-1000 zirconia crowns.

✔ Extended Durability – 5-8x longer lifespan than traditional DLC-coated burs (80-150 crowns/bur), significantly reducing consumable costs.

✔ High Efficiency & Stability – Diamond’s extreme hardness + low friction coefficient ensures consistent high-speed performance without degradation.

✔ Wide Compatibility – Compatible with leading dental milling machines (VHF, Roland, Arum, Imes icore, Upcera, Aidite, Up3d, Jiny, etc.).

Declaration: The purpose of reprinting this article is to convey more information. If there are any source labeling errors or infringements on your legitimate rights and interests, please contact our company's official website with proof of ownership, and we will promptly correct and delete them. Thank you.

Follow us on Facebook

Telephone:

0755-27418980 Zhongyu Green Industrial Park, Matian Str, Guangming Dist, Shenzhen

Zhongyu Green Industrial Park, Matian Str, Guangming Dist, Shenzhen

info@vpttools.com

info@vpttools.com